1.The construction of slurry pool is completed and the site land is hardened and leveled.

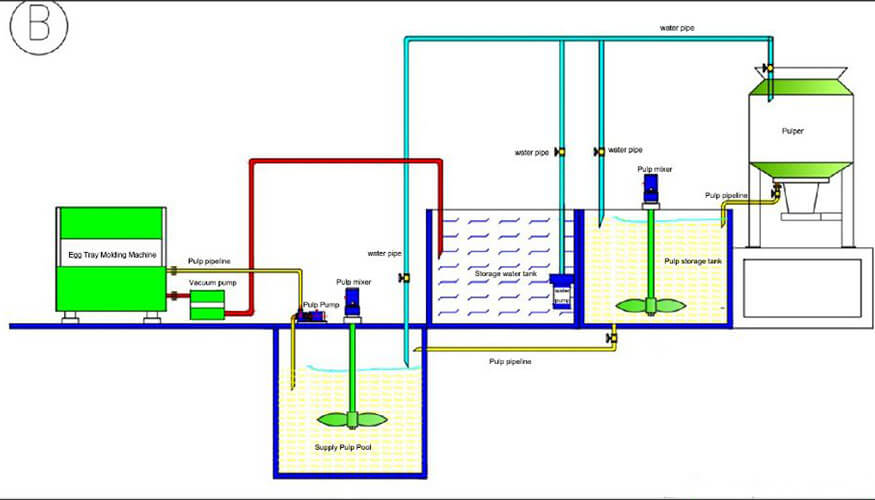

2.Determining the position of the hydrapulper according to the plane layout Diagram, Pulp outlet ,Release the finished pulp directly to the pulp storage tank

3.A 900 diameter agitator is arranged on the pulping tank.

4.Adjust pulp in the pulping tank and put it in the Pre-emptive pool(pulp tank before the machine),Layout of diameter 1500 agitator and Slurry pump on the Pre-emptive pool

5.Slurry pump exit Connecting molding machine exit

6. The moulding machine is arranged according to the layout of the plane, and the outlet A is the Overflow port, Connecting pipe back to the Pre-emptive pool. B exit is pulp entrance,connect the Slurry pump exit , D entrance connect the air compressor entrance, C entrance connect the vacuum pump entrance, Molding machine E connecting vacuum pump entrance

7.The vacuum pump and the air compressor are reasonably arranged according to the scene and the molding machine. The vacuum entrance use Piped connect to the water pool.