Model:1575

Capacity:8-12 tons per day

Gram weight:90-250g/㎡

Raw material:waste carton paper

Pulp is the first step to making kraft paper.

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibres from raw material

Papermakingline can use waster paper,recycled paper ,tree ,bamboo ,reed ,wheat straw cotton and bagasse as raw material to make good quality craft paper,finished product can be paper roll, tissue paper, toilet paper, culture paper , Kraft paper, newspaper etc.

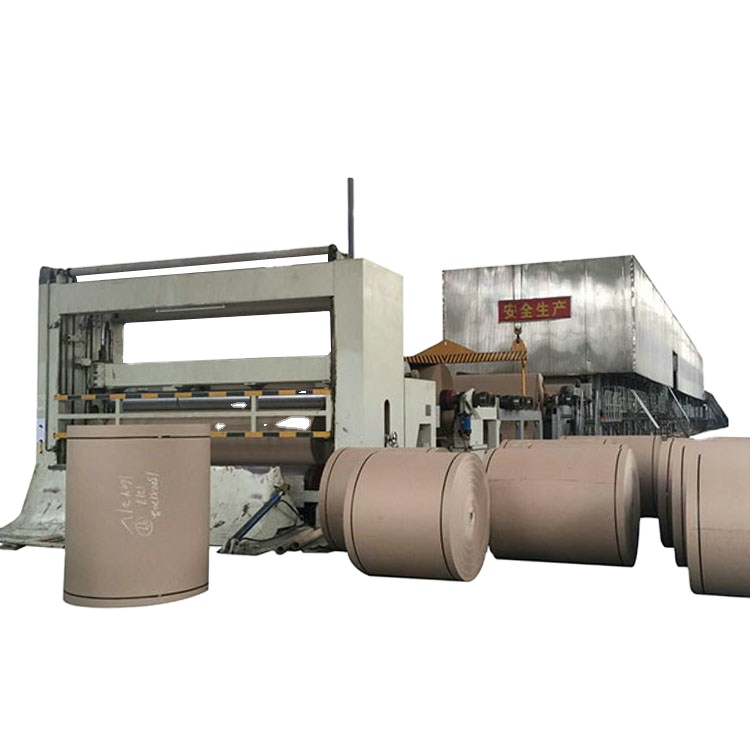

The kraft paper machine can make the paper pulp into kraft paper jumbo roll,and the jumbo roll paper can be done Kraft paper bags, paper tubes, paper cans, cartons

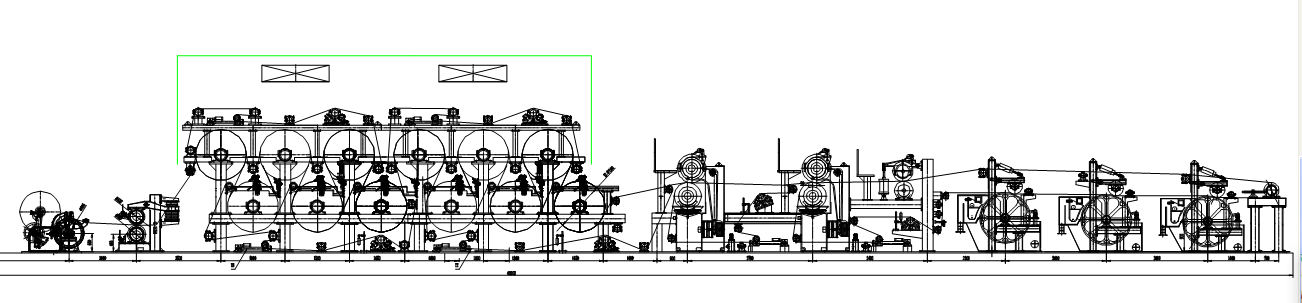

jumbo roll kraft brown paper recycling making machine 10 tons a day consists 7 section:wire section,press section,dryer section,reeling section,sizing section,calender section,rewinding section.The former 4 section is main for jumbo roll kraft brown paper recycling making machine 10 tons a day,and the last 3 section are optional for customer.

1.Wire section :Usually,it has two kinds of wire part,one is cylinder mould wire type,the other is fourdrinier wire type.Its function is to dewater from the wet paper

2.Press section:function is to press water from wet paper,after press,the dryness of the paper is range from 22% to 46%.

3.Dryer section:function is to make paper dry,after the paper come out from the dryer,the dryness can be 92%-95%.

4.Reeling section: function is to reel the paper into jumbo paper roll.

5.Sizing section:Sizing machine's funtion is to add the starch to paper and let paper is waterproof.(optional)

6.Calender section: function is to let the paper surface smooth.(optional )

7.Rewinding section:function is slit&rewind the jumbo roll paper to small roll.(optional )

|

Machine Model |

1575 |

|

Paper Width(mm) |

1575mm |

|

Voltage |

380V 50HZ |

|

Output |

8-12T/D |

|

Raw material |

Waste Paper Carton |

|

GSM |

90-250g/㎡ |

|

Working speed |

40-80 m/min |

|

Power Configuration |

380V 50HZ |

|

Warranty |

1 Year |

|

Drive way |

AC frequency conversion speed regulation. |

Dear Sir/Madam,

Thanks for your interesting in our Kraft corrugated fluting paper making machine.

In order to recommend proper machine and make detailed technical proposal and exact offer for you soon ,could you please tell us the following technical parameters?

1.What kind of paper do you want to produce?

Kraft paper,Fluting/corrugated paper? Liner paper?

2.What kind of raw material you will use?

(1)100%waste paper?

(2)waste paper+virgin pulp?

(3)wheat straw,bamboo,wood,bagasse,reed,hump?

3.How many tons do you want to produce per day(in 24 hours)?(t/d).

4.Do you have requirement about paper weight (g/m2) and jumbo roll paper width(mm)?

We are responsible for decision, installation, debugging ,training technical personnel, We have professional technicl team.Experts can be sent to the site to guide the installation,customer need to have workers on site provide support tools.