The egg tray machine production line is a waste paper recycling production line. The raw materials are waste paper products, mainly waste paper boxes and waste corrugated paper.

The egg tray production line is divided into three systems: pulping system, forming system, and drying system.

The main pulping equipment is a pulper. The function of the pulper is to convert waste paper boxes into pulp under hydraulic action.

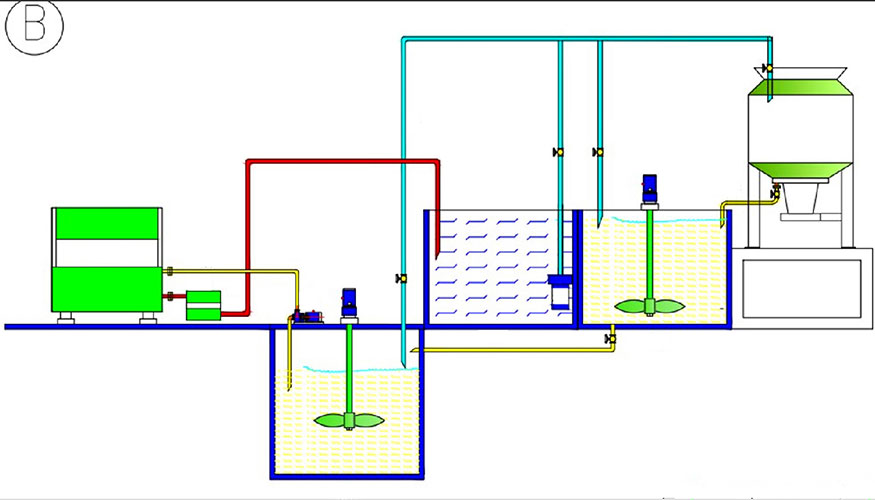

Then our production preparations require the construction of three tanks, two above-ground tanks and one underground tank.

The yellow tank on the ground is the tank for storing pulp. The pulp in the pulper will flow into the pulp storage tank, and then the pulp concentration will be adjusted in the pulp storage tank.

When the slurry tank opens the valve, it will flow into the underground slurry supply tank.

The pulp in the underground slurry supply tank is pumped to the forming machine by the slurry pump.

Under the action of the vacuum pump, the forming machine absorbs the paper fibers in the forming machine, and the paper fibers are formed on the mold, and then the air compressor and the vacuum pump cooperate to transfer the formed products to the drying mesh.

The configuration of our drying equipment is specifically related to the output of the customer, the size of the customer’s factory, and the scope of the customer’s budget. The drying equipment needs to be customized according to the needs.