Model:1575/1880/2800

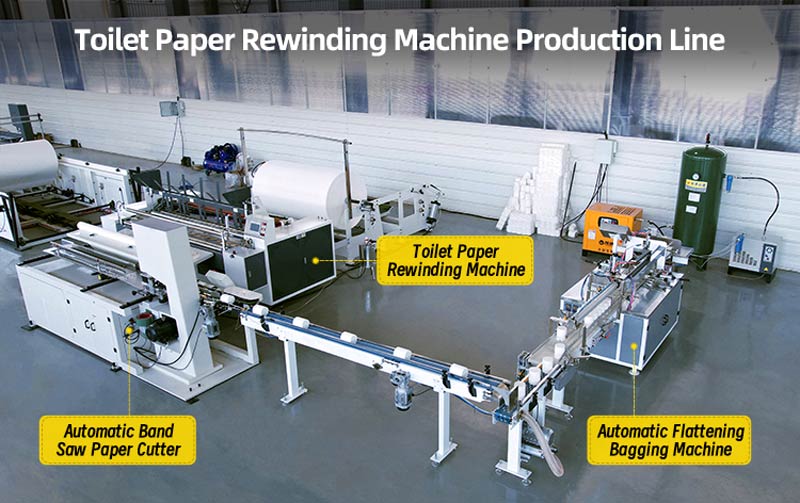

Fully or semi-automaticproduction line

Finished product:Toilet paper roll,kitchen towel roll

Suitable For Small Business

The toilet paper rewinding machine is through rewinding the jumbo roll, and then become jumbo paper rolls into two-layer or three-layer small toilet paper roll.Toilet paper roll rewinding processing machine, have core feeding unit, can do both with and without core. Raw material from jumbo roll after full embossing or edge embossing, then perforation, end cutting and spray the tail glue become a log. Then it can working with cutting machine and packing machine to become the finished products.

1.PLC intelligent touch automatic rewinder machine

2.Fully automatic band saw paper cutting machine

3.Single -roll automatic packaging machine

4.Muti-roll packing machine

5.Supporting customized conveyor belt and sorting machine

Mainly imported electrical components, Japan Matsushita inverter, Omron PLC, packaging machine host with 12 thick steel plate welding, stainless steel countertops, with mechanical anti-cutting and photoelectric anti-cut function.

1.Using PLC computer to program the finished paper in the rewinding process to achieve the tightness and looseness of the different tightness to solve the looseness of the finished product due to long-term storage.;

2.Full-automatic rewinding machine can choose double-sided embossing, gluing compound, which can make paper more soft than single-sided embossing, the effect of double-sided finished products is consistent, and each layer of paper does not spread when used, especially suitable for processing;

3.The machine is equipped with processing unintentional, solid, paper tube toilet paper, which can instantly switch between products, and can also be selected according to user needs;

4.Automatic trimming, glue spraying, sealing, and shafting are completed synchronously, so that there is no paper loss when the roll paper is cut into the band saw and packaged, which greatly improves the production efficiency and the grade of the finished product. Easy to enable;

5.Pneumatic belt feeding, double reel and each axis of the original paper have independent tension adjustment mechanism.

| Product name | Automatic Toilet Paper Rewinding Machine |

| Machine model | FY-1575/1880/2100/2400/2800/3000 |

| Base paper roll diameter | 1200mm (Please specify) |

| Jumbo roll core diameter | 76mm (Please specify) |

| Punch | 2-4 knife,spiral cutter line |

| Control syetem | PLC control,variable frequency speed control,touch screen operation |

| Product range | core paper, non core paper |

| Drop tube | manual and automatic (optional) |

| Working speed | 150-280 m/min |

| Power | 220V/380V 50HZ |

| Embossing | Single embossing,double embossing |

| Finished product launch | Automatic |