Model:Fy-WF2*2

Capacity:1000-1500 Pcs/Hour

Mould:600*800×2

Dryer:Customized

Fuyuan factory supplies more than 100 specifications of pulp molding machinery and equipment, including high-quality egg tray production lines, industrial packaging paper tray production lines, and other pulp molded product production lines. There are fully automatic and semi-automatic product lines. Various production capabilities meet the requirements of various customers.

The company has complete institutions, such as product development, machine manufacturing, mold processing and production process testing. In addition to providing customers with a full set of production lines including equipment and molds, there are also complete integrated technical services, such as process technical support and personnel training.

After the customer purchases our company’s entire plant equipment, our company can provide production process formulas and technical guidance for the entire production process to ensure the smooth realization of mass production by customers.

Site Area: Production workshop 100 square meters, drying area 1000 square meters, warehouse 300 square meters or more Suitable for the production of various types of egg trays, bottle trays, shoe supports, fruit trays and other pulp molded products.

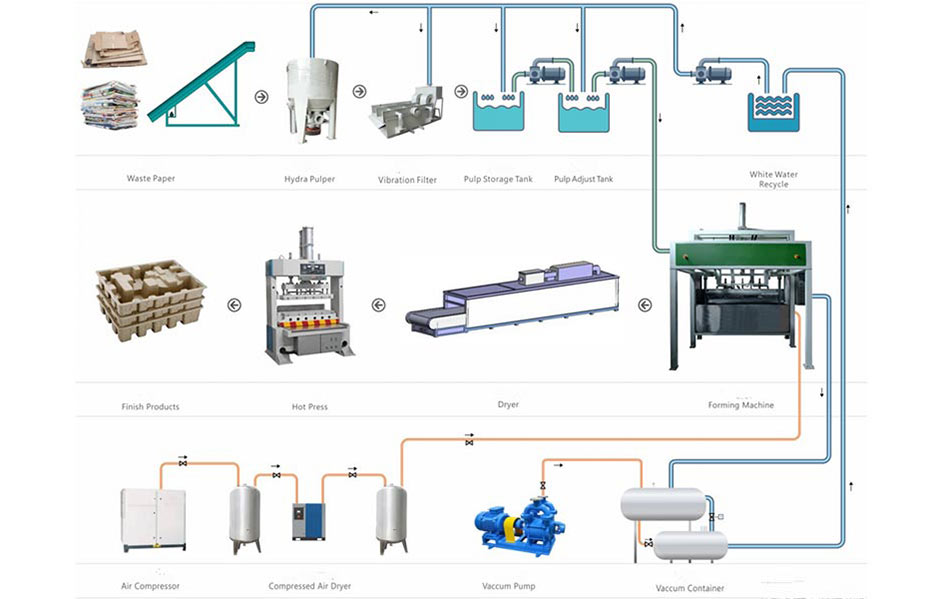

1. Pulping System

2. Forming System

3. Drying System

4. Hot Press Machine

1. Reciprocating structure, the bottom mold reciprocates up and down to suck slurry, and the top mold sends out products back and forth;

2. The products are automatically produced and sent to the drying line;

3. The template size is 1600*800mm; each template can hold 6 sets of 30 egg tray molds;

4. Cycle time: 12~18 seconds/cycle to produce 75g egg tray.

5. Capacity: 1000-1500 pieces/hour for 30-pack egg trays;

6. The whole production process is controlled by PLC intelligent computer, including parameter setting, production plan, counting, alarm and other functions; all can be set and displayed on the man-machine interface;

7. Automatic mold washing and automatic burr washing function;

8. Pulp bucket and control box are made of SUS304 stainless steel;

9. PLC + touch screen man-machine interface operation control.

10. Major brands of electronic control components (Fuyuan): Inovance, CHNT

11. Quality of main pneumatic components: SMC/ARK.

|

Machine Model |

Fy-WF2*2 |

|

Processing Type |

Paper Pulp Molding Product Equipment |

|

Production Capacity |

1200-1500 Pcs/Hour |

|

Total Power |

60kw |

|

Weight |

5000kg |

|

Waste Paper |

120kg/h |

|

Water |

300kg/h |

|

Workshop Area |

100Sqm |

|

Voltage |

220v/380v |

|

Raw Material |

Any Kind of Waste Paper. Like Old Newspaper, Magazines, Books, A4 Paper, etc. |

|

Mold Material |

Plastic or Aluminium |

|

Mould Type |

600*800×2 |

|

Drying Way |

Customized |

|

Finished Products |

Egg Tray, Fruit Tray, Shoe Tray, Wine Tray, Industrial Products Packaging, etc. |

|

Quality Standard |

CE, ISO |