Many friends are worried that egg tray production line is too complicated to start as a new business, but in fact egg carton production only requires Five Steps, let’s quickly learn the key points!

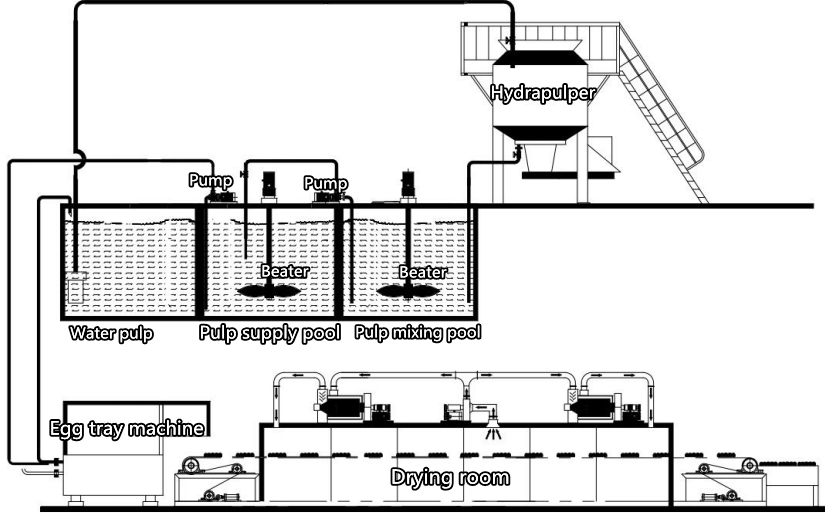

Step 1: Put the prepared raw materials, such as waste paper carton,newspaper etc. Into hydrapulper, making paper pulp by the shear force and friction force of water, transfer the prepared pulp into Pulp mixing pool.

Step 2: Transfer the pulp and water into Pulp supply pool, filtering the impurities out of paper pulp at the same time,adjusting the concentration of the pulp. Now you can add such as color agent, waterproof and so on materials by your needs, stirred sufficiently.

Step 3: Pumping the prepared paper pulp from Pulp supply pool by pulp pump into egg tray molding machine, then the mold on the top sink into paper pulp completely, under the pumping action of the mold which has vacuum action in the back, pulp is adsorbed on the surface of the mold, at the same time, water in the pulp is pumped out, then the wet egg tray was formed on the surface of the mold.

Step 4: The wet egg tray is transported through a conveyor belt into the drying room, where it is dried under the high temperature. The finished egg tray is of excellent quality.

Step 5: When the molding machine working, the water in the pulp will pumped out by the vacuum pump,then discharging the waste water into waste water pool. You can ransfer the waste water into hydra pulper and mixing pool by waster paper pump to recycled used.